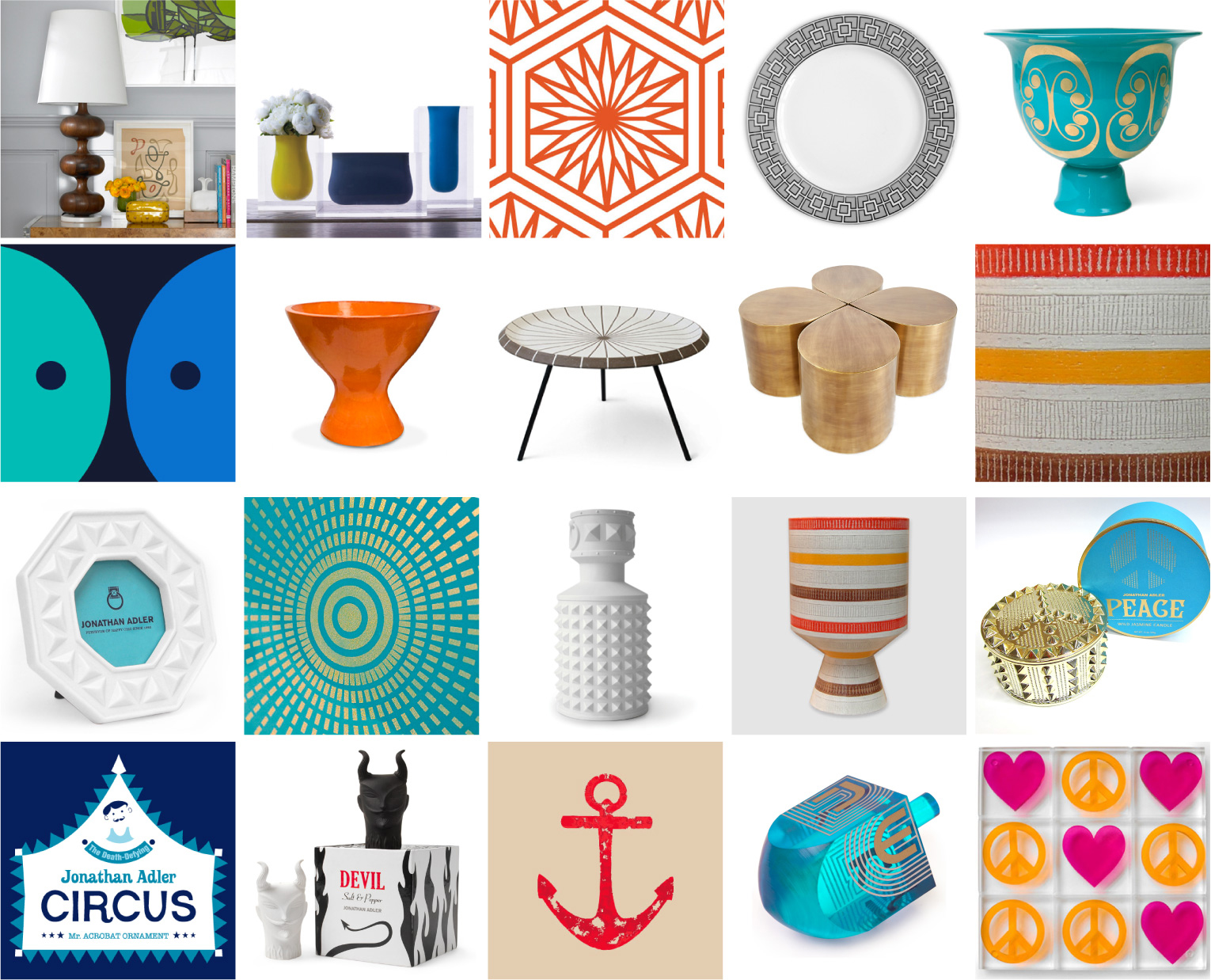

In this fast-paced environment I managed all aspects of the design process from brainstorming ideas, sketching, designing object forms, developing patterns, selecting colors, creating spec sheets, designing packaging and communicating with vendors. After prototypes were received I would test the products, check for corrections and provide revisions for production. Here is a small selection of my design work and a glimpse into my role.

Each product required a certain amount of design research including: material research, ergonomics, manufacturing methods, historical and pattern references, color limitations, safety requirements and testing and market research.

In my final year at Jonathan Adler I designed and managed the production of 220 SKUs that went to market. About 40% of our designs would not make it past design or prototyping. Each designer tracked and managed vendor relations, from sourcing, to spec sheets, to product revisions, manufacturing adjustments, packaging and approvals. These stages were tracked in spreadsheets and reviewed weekly in production meetings to ensure our projects moved forward on time and budget.

Our products were presented and sold at trade shows and adhered to seasonal schedules. When I started I was designing Christmas packaging in July for items that would be on the shelf in November. Factor in prototyping time overseas, revisions, approvals and freight shipping time and it was difficult to feel confident that products would be delivered on schedule. Since I was the liaison between our pottery studio and the factory I kept pushing these products forward to give me more time to design graphics and packaging in advance. By the time I left Jonathan Adler we had Christmas ornaments and packaging being conceptualized and started 14 months in advance giving the design, purchasing and sales teams more flexibility and opportunity for success.

Part of my role was to interview, hire and manage interns for the design team. I would welcome them to the organization, train them on our process and have them research and design parts of projects. I provided creative direction, learnt how to guide projects with productive feedback and provided work and portfolio advice. I also met some amazing designers along the way.

Jonathan Adler is not lacking in vision and often he could dream it but we couldn’t find the right factory or artisan to make it. The design team was always looking for manufacturers, products or processes that we could use. Sometimes this could happen right away and other times it would take multiple prototypes and perseverance to get it right. The fine details for each product needed to be considered and addressed.

When sending designs to prototype they were thought through as much as possible. When we received a prototype it needed to be reviewed thoroughly from its construction, quality, durability, ease of use, packaging, ease of shipping and cost. A teapot might need to have its spout lowered to pour more effectively. A lamp might need its shade shortened to reach the switch more comfortably, a hook on an ornament would need to be moved to balance the weight. Dishes would be run through the dishwasher to test the durability of the artwork. Colors needed to be matched to pantones. The weight of stand on a sculpture might need to be decreased to reduce cost. The small details made a huge difference in the usefulness and viability of each product and whether we could bring it to market.